GREENID CO

Unit 5, No.5,Sharifi St.,Behnam St.,

Kashani Blvd, Tehran , Iran

©Copyright by GREENID

شرکت گرین آیدی بنا به در خواست ، با استفاده از بهترین مدلهای طراحی اجزاء شرکت های معتبر در زمینه سیلوی ذخیره مواد توانایی طراحی انواع سیلو با ظرفیت های مختلف جهت صنایع سیمان ، صنایع معدنی را دارد

در طراحي انجام شده بهترين مدلهاي طراحي اجزاء از شركتهای معتبر

.انتخاب شده و در اختيار است

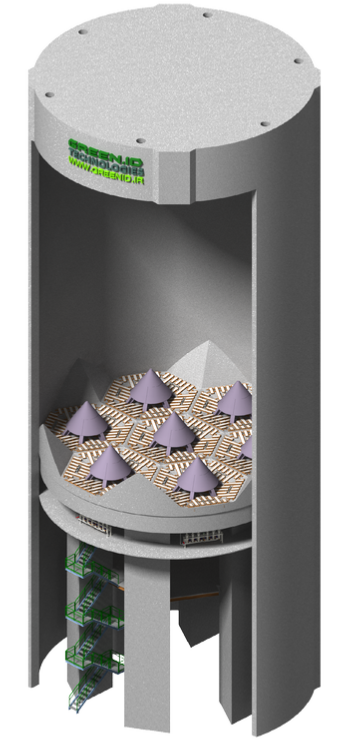

The blending silo is simultaneously used for a continuous blending process as well as for raw meal storage.

Unique Silo Bottom

The bottom of the CF silo is specially designed to maintain an optimal flow pattern during extraction of the raw meal.

Featuring seven identical, hexagonal extraction points, the silo has a large conical, steel cover at the center of each hexagonal sector. These steel cones maintain an optimal flow pattern, increasing blending efficiency.

The cones also:

- Relieve the pressure above the outlets

- Ensure extraction from the aerated part of the silo bottom

The CF silo’s unique bottom is designed to maintain an optimal flow pattern during extraction of the raw meal.

Other design highlights

- Silo top with manholes, overpressure and under pressure valves and level indicators

- Raised, above-ground silo bottom with kiln feed or blending tank underneath

- 42 separate sub sectors in the silo bottom, all with aeration units

- Shut-off valve with slide gate on each outlet for easy maintenance

Well-proven homogenizing

and storage system

Control system

The CF silo’s extraction system is governed by a programmable control unit. This allows you to select the optimum flow rate distribution based on local requirements and conditions. Silo control is maintained either via a locally installed programmable control unit or by a central programmable control unit.

As an additional advantage, the control unit can be configured to include the FLS-LOW (Loss-Of-Weight) system for control of the kiln feed flow rate.

CF silo with FLS-LOW kiln feed control system.

Silo Catalog

Silo Catalog