GREENID CO

Unit 5, No.5,Sharifi St.,Behnam St.,

Kashani Blvd, Tehran , Iran

©Copyright by GREENID

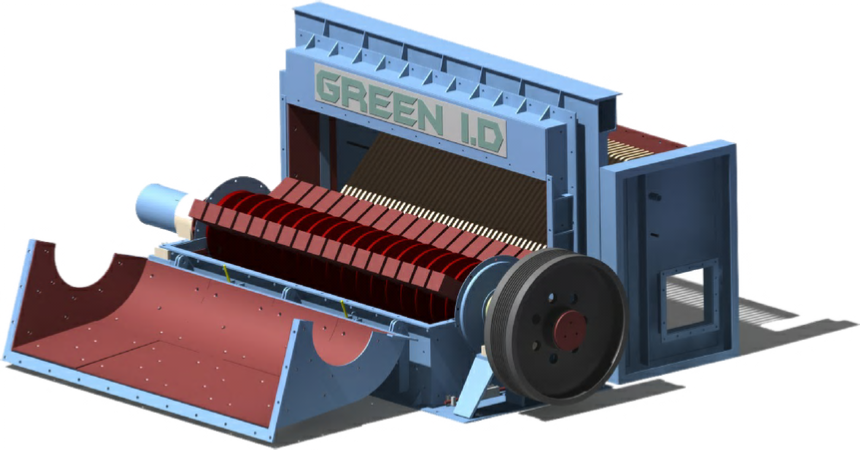

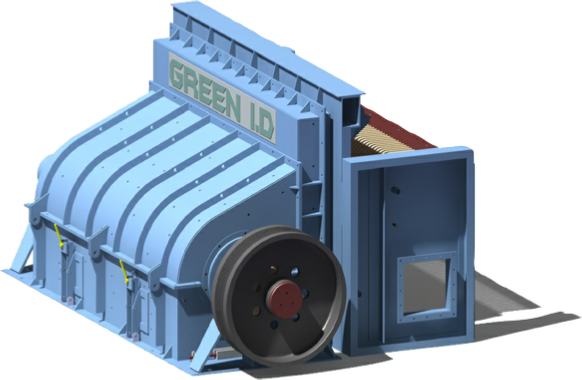

The cement clinker burning process produces agglomerated balls of clinker which may be so large as to make their further passage from the kiln for storage or grinding extremely difficult.

To avoid such complication, these balls are removed at the clinker cooler outlet and reduced in size by clinker crushers before being returned to the main clinker flow.

In both cases crushing is performed by hammers pivotally mounted between rows of hammer discs. The hammer extends radials during rotation, and crushing is effected by the impact between clinker balls and hammers the resulting lumps being dashed against the crushing plates. In the PGC cooler the wholly or partially crushed clinker is hurled back to the grate cooler for further cooling.

GREENID clinker Crushers are equipped with adjustable jaws which can not only be set at the required degree of crushing, but can also be adjusted to compensate for hammer wear.

Wear is concentrated on the hammer face, and the hammers can be reversed when worm to expose the opposite surface

GREENID Clinker Crusher is driven by V-belts powered by electric motors.

GREENID Clinker crusher requires little maintenance. It is advisable, hammer unit in reserve to facilitate rapid change over

GREENID Clinker Crushers are easy to service, the top section swiveling open to facilitate access to internal components.

… Hammer Crusher

Clinker Breaker