GREENID CO

Unit 5, No.5,Sharifi St.,Behnam St.,

Kashani Blvd, Tehran , Iran

©Copyright by GREENID

این شرکت توانايي طراحي ، ساخت ونصب انواع بگ فیلتر (جت پالس فیلتر ) را در تمامي ابعاد استاندارد جهت صنايع مختلف از جمله سيمان ، فولاد ، صنايع معدني و غيره را دارد

Construction

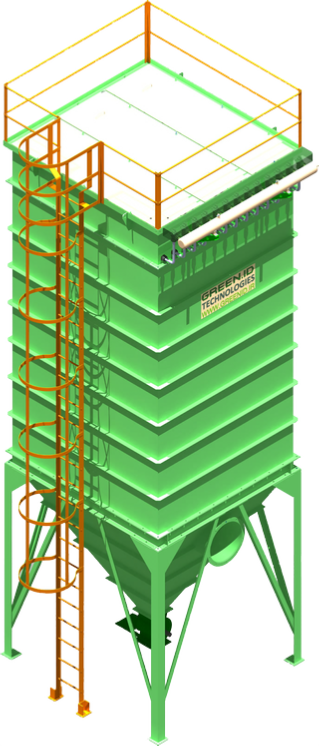

GREENID bag filter dust collectors are constructed from bolt together folded sheet metal panels and are available in 1.5 mm ,3 mm and 4 mm thickness as standard. The material thickness of GREENID’s dust collector panels has been optimized to minimize cost whilst maintaining strength.

Panels can also be fabricated in Stainless Steel for highly corrosive environments. All panels are connected with high tensile fasteners for strength and corrosion protection.

GREENID dust collector legs are fabricated from heavy Square Hollow Section steel as standard, making them suitable for heavy duty industrial sites. All GREENID dust collectors are structurally certified to withstand high wind loadings.

The dust collector legs are hot dip Galvanized as standard for long lasting corrosion protection. Standard support structures accommodate hoppers with bins, rotary valves and screw feeders. The foot print for every leg is100% symmetrical making it easy to mark out cast-in anchor positions in concrete and trouble free installation.

GREENID dust collectors have been designed with smooth internal surfaces to minimize dust hang up in the filter chamber and hopper. To enable this feature, the folds on the panels are on the outside. To minimize corrosion on the outwardly facing folds, notches are provided on all panels to permit effective drainage.

Filters

GREENID bag filters are made from heavy duty Polyester. Antistatic media is supplied as standard. GREENID cartridge filters are made from either a Cellulose Polyester Blend or Spun Bonded Polyester media. The spacing between filters has been selected for effective and reliable dust release. Optimal filter spacing makes GREENID dust collectors ideal for dusts that have a tendency for bridging such as stringy and fibrous materials.

Cleaning System

Compressed air tanks for pulse cleaning are hot dip Galvanized for long lasting corrosion protection. Every air tank is pressure tested and certified to AS 1210-1997. Pulse valves are supplied as 45 mm as standard for high capacity pulsing. Pulse valve coils are supplied as 24 VDC for safety during service.

Dust Inlets

Dust collector dust inlets are positioned either in the hopper(s) in the filter chamber (beneath the level of the filters). Inlet plenums are also available for abrasive dusts.

Accessories

Various dust collector accessories are available from GREENID such as screw feeders, ladders and access platforms, rotary valves, emission monitoring equipment, bin level sensors, explosion vents, fans, Silencer , electrical control panels and ducting.