GREENID CO

Unit 5, No.5,Sharifi St.,Behnam St.,

Kashani Blvd, Tehran , Iran

©Copyright by GREENID

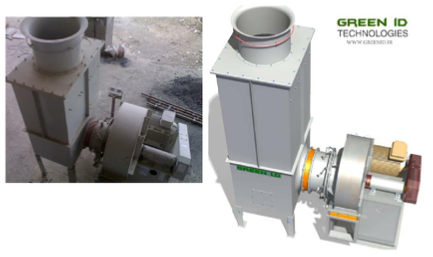

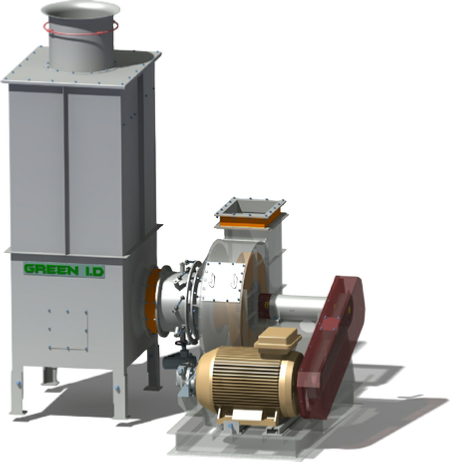

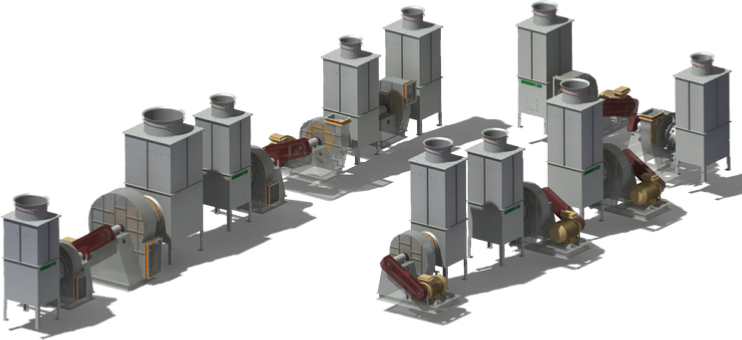

Due to the abrasive nature and the clinker dust in the surroundings, the cooler fan must be suited to the possible wear from these conditions.

Normally, size, RPM and power consumption of a fan type is specified in process diagrams. The fan must be sized for the necessary air flow at the nominal kiln production rate. The calculated fan capacity includes a reserve capacity to make possible adjustments of the amount of cooling air at various operating conditions

Some plats specify larger spare capacities to protect the grate against thermal load. Furthermore, the fan size ensures that the fans under normal operating conditions work in the high efficiency area of fan P-V diagram.

Dampers used in conjunction with centrifugal fans provide a simple, reliable and cost effective means for controlling air systems.

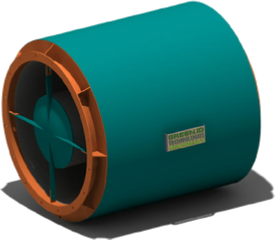

Gas flows through aerodynamically designed passages and around central core which are filled with an appropriate acoustic absorption material to provide the noise reduction desired. Silencer can be installed horizontally or vertically on the inlet or discharge of any fan or remotely in the air system.

Sound pressure in 1 m distance of fan, ductwork connected on both sides 84 dB

Fan & Silencer

Silencer Products:

- Silencer for air inlet fan

- Silencer for air outlet fan

- Silencer for axial fan

Silencer Catalog

Silencer Catalog