GREENID CO

Unit 5, No.5,Sharifi St.,Behnam St.,

Kashani Blvd, Tehran , Iran

©Copyright by GREENID

Nothing can shake them

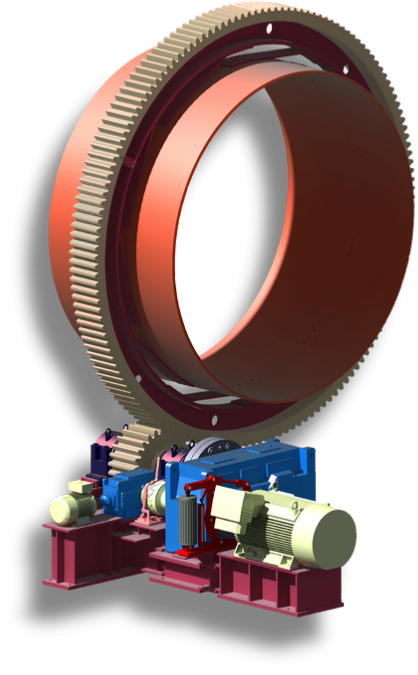

The event, smooth operation of the kiln and optimal contact pattern with the pinion is achieved by mounting the girth gear on the kiln shell using tangential springs. The centered action of the girth gear is adjustable.

Feel free to create friction

Alternatively, it’s possible to transmit the drive torque from the rollers to the tire. This type of drive is only suitable for two station kilns. The characteristics of both types of drive are listed in the adjacent table.

Hydraulic drives – acting directly or via gears on the drive shaft – also permit smooth kiln operation but are less efficient. This is why they are also considerably less economical.

This is where the power is

The drive units consist of the main and auxiliary drive. Variable speed AC or DC motors are used as drive motors. The auxiliary drive is furnished with an electric motor and / or a combustion engine. In conjunction with multi-stage or planetary gearboxes and elastic, practically maintenance-free couplings, the drives offer maximum operational safety and outstanding efficiency.

This is our drive

The drives for all kilns are designed for the reliable operation of the kiln under any operating conditions. This means that even greater safety factors and torque reserve, are installed for nominal operation. All drive components are designed for the installed motor torque plus all safety factors and not only for effective torque generated at nominal capacity. The installed reserves and safety factors ensure the extremely flexible operation of the kiln, including higher clinker throughput, without overloading the drive.